We’ve been experimenting a bit with metal casting recently. Pewter is a very easy metal to work with. Because of it’s low melting point, it can be poured into molds of a variety of materials. You can even melt it at home on the stove! At the Node, one of our members has a small electric melting pot so we used that to melt the pewter and pour it into an acrylic mold. We tried this last month and then again yesterday and the results are great.

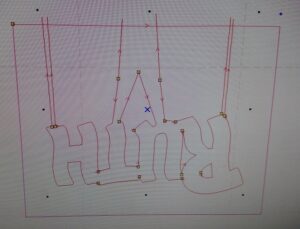

The first step was to create the design on the computer. The trick is to make sure each piece is connected, and sprued and vented properly. When we pour metal into the mold the air inside the mold has to have a way to escape. We added vent lines on either side and a big pour spout in the middle.

The shape had some internal features like the hole in the top of the R, the piece between the R and the U, and the big piece between the U and the T, so those pieces of acrylic were cut loose. The vent lines and pour spout also made some separate pieces, so they had to be attached carefully. We cut a second rectangle and glued the loose pieces to the rectangle using acrylic welder.

We then sanded a small pour spout into the top of a piece of wood and clamped the mold in between to wooden pieces.

The metal was melted and at around 550 degrees. A ladle was used to scoop up and pour a little bit of metal into the opening. The metal flowed down into the mold, displacing the air which flowed out the side vents.

After the mold cooled, the clamps were removed, the wood blocks were separated, and the acrylic mold was snapped apart to remove the cast pewter. The vent lines and sprues were removed with pliers and the final piece still has to be sanded and polished.

You can learn how to do this too and make one for yourself in an upcoming “The More You Node” workshop! Stay tuned for details.

2 thoughts on “Metal Casting in acrylic laser-cut molds”

Why does it work?

Which kind of acrylic did you use? I assumed that the mold has to have a (much) higher melting point so I wonder how it’s possible to use this combination of materials.

Cheers (Greetings from Fablab Munich)

Nikolas

Basically, it’s super thin and only ~500ºF so it cools down very quickly. You can cast into a lot of materials. We just used regular acrylic clamped between two pieces of MDF, but I’m sure you can do it with many materials.